In today’s industrial landscape, the durability of components is more crucial than ever. Brass cable glands, essential for securing cables, have become a popular choice in various sectors. But what makes them so reliable, especially in harsh environments? Let’s dive into the world of brass cable glands and explore their remarkable resilience.

Understanding Cable Glands

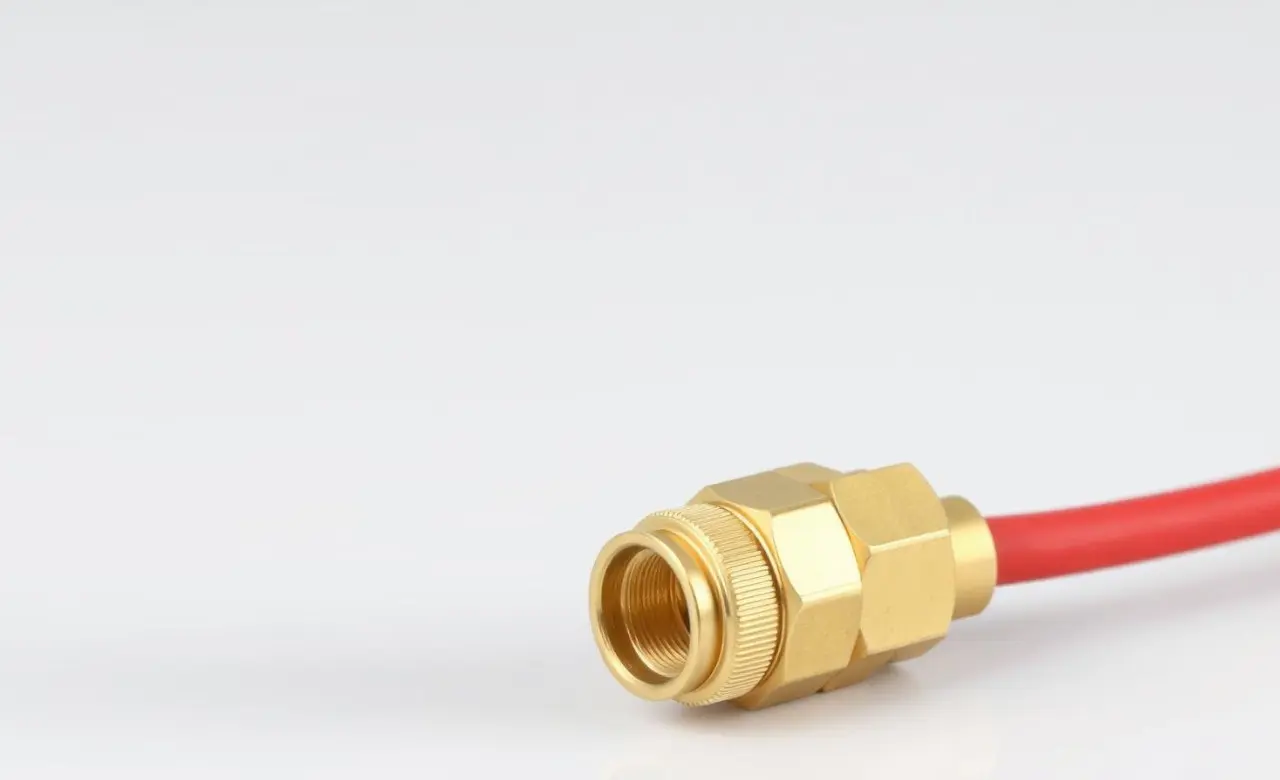

Cable glands are devices designed to attach and secure the end of a cable to an equipment. They provide strain relief and ensure the conductivity of the electricity passing through. Brass cable glands, in particular, are prized for their robustness and reliability.

Essentially, cable glands perform two fundamental roles – securing the cable mechanically and maintaining the ingress protection (IP) level of the installation. They cater to various cable types and diameters, making them versatile and indispensable in electrical setups. By safeguarding the cable’s end from environmental stresses, they help prolong the system’s overall lifespan.

The role of cable glands in an electrical system cannot be overstated. They ensure the safe composition of cable installations and connections, which is pivotal for operational continuity. In industries where safety is paramount, having reliable cable glands like those made from brass becomes even more critical.

Why Brass? The Key Properties

Brass is an alloy made of copper and zinc, known for its high durability and resistance to corrosion. These properties make brass an excellent material for cable glands, especially in environments subject to extreme conditions.

The strength and versatility of brass are unparalleled when compared to other materials used for cable glands. For instance, brass has exceptional tensile strength, which means it can withstand significant force and pressure without breaking or deforming. Additionally, brass possesses inherent anti-corrosive properties, making it ideal for use in wet or chemically aggressive environments. This resistance is crucial in ensuring the long-term reliability of cable installations in industrial settings where exposure to moisture and corrosive elements is frequent.

Another noteworthy aspect of brass cable glands is their electrical conductivity. Unlike other materials, brass provides a consistent and reliable conductive path, which is fundamental in ensuring efficient and safe electrical transmission. This makes brass particularly advantageous in applications where maintaining electrical integrity is non-negotiable.

Performance in Corrosive Environments

One of the standout features of brass cable glands is their ability to withstand corrosive substances. This makes them particularly useful in industries like oil and gas, where exposure to harsh chemicals is common.

In environments prone to significant wear and tear, such as coastal areas or chemical processing plants, brass cable glands exhibit remarkable resilience. The nickel-plated finish on some brass cable glands further enhances their corrosion resistance, providing an added layer of protection against environmental degradation. This not only extends the life of the cable gland but also ensures sustained performance in demanding conditions.

It’s also worth noting that brass cable glands help in preventing the ingress of common contaminants such as dust, water, and even oils. This sealing capability is vital in preserving the integrity of the cable connections, making brass cable glands a preferred choice for maintaining operational efficiency in challenging settings.

Handling Extreme Temperatures

Brass cable glands are also effective in extreme temperature conditions. Whether in freezing or scorching environments, they maintain their structural integrity, ensuring continuous protection for cables.

The thermal stability of brass is particularly remarkable. It can endure temperatures ranging from very low to very high without losing its physical properties. This makes brass cable glands suitable for use in environments with wide temperature fluctuations, such as those found in desert installations or polar regions. The ability of brass to withstand such extremes is a significant advantage for industries requiring reliable components that won’t fail under thermal stress.

Moreover, brass is known for its excellent thermal conductivity, which allows for efficient heat dissipation. This characteristic helps in preventing overheating of electrical connections, further contributing to the overall safety and reliability of the electrical system. Whether dealing with high-power installations or systems exposed to external heat sources, brass cable glands provide a robust solution.

Ease of Installation and Maintenance

Another advantage of brass cable glands is the ease of installation and maintenance. Their design allows for quick and secure fittings, reducing downtime and ensuring operational efficiency.

The ergonomic design of brass cable glands simplifies the installation process. They typically come with user-friendly fittings that allow installers to secure cables with minimal effort while ensuring a tight and reliable seal. This ease of use is particularly beneficial in large-scale industrial applications where time and efficiency are paramount.

In terms of maintenance, brass cable glands require minimal attention once installed. Their durable construction and resistance to environmental stressors mean that they can perform effectively over long periods without the need for frequent inspections or replacements. This reliability translates to significant cost savings in maintenance and operational expenses, providing a high return on investment for industries opting for brass over other materials.

Applications Across Various Industries

Brass cable glands are used in a wide range of industries, from marine and telecommunications to manufacturing and aerospace. Their versatility and durability make them a preferred choice for safeguarding cables in demanding settings.

In the maritime industry, for instance, the robustness of plated brass glands equipped with an IP68 rating ensures that they can withstand the harsh conditions of seawater exposure. These brass glands provide an impermeable barrier against moisture ingress, which is crucial for maintaining the operational integrity of maritime electrical systems.

In the telecommunications sector, the superior electrical conductivity and mechanical strength of brass cable glands ensure secure and efficient connections, even in outdoor or underground installations where they are exposed to varying environmental conditions. The ability of brass cable glands to offer sustained and reliable performance makes them indispensable in this industry, where connectivity and uptime are critical.

In manufacturing and heavy industrial applications, the durability of brass makes it an ideal material to resist mechanical stresses and impacts. The anti-corrosive properties further ensure that key installations remain functional despite exposure to potentially damaging substances and conditions. This reliability is why brass cable glands are trusted components in such high-stakes environments.

The Unmatched Reliability of Brass Cable Glands

Brass cable glands truly stand out in their ability to withstand harsh conditions, making them an invaluable component in industrial applications. Their robust construction, resistance to corrosive materials, and ease of installation make them the ideal choice for ensuring cable security and longevity. Next time you’re considering which type of cable gland to use, remember the impressive benefits of brass – a durable and reliable option.